How to quickly choose the best bonding method for the touch screen ?

In our daily communication with customers, one of the most frequently asked questions by our customers is: Is our product suitable for OCA bonding or air bonding ? In order to communicate more effectively with customers and let the business elites quickly know which products are suitable for OCA bonding and which products are suitable for air bonding. On Nov 22, Leadtek engineer Mr Tom organized a product training for business elites with the theme: How to quickly choose the best bonding method for the touch screen ?

Tom mainly introduced from the following two aspects:

1. For the backlight uses an iron frame or a plastic frame, the polarizer is protruding and higher than the plastic frame of the backlight, it is recommended to use OCA bonding process. For the plastic frame with the polarizer lower than the backlight of the LCD module, it is recommended to use air bonding process.

2. Due to the different raw materials used in the LCD module, if the LCD module is TN display,water ripples will be formed on the surface if the LCD module is optical bonded, and air bonding will be the best bonding method. If the LCD module is IPS display, please refer to item 1 above to select the corresponding bonding method.

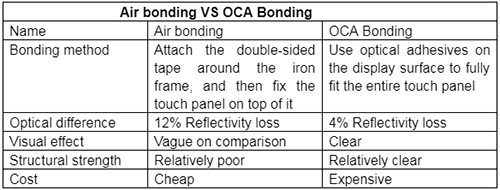

The following is an explanation of the two bonding techniques:

In terms of bonding technology, the commonly used methods in the industry include: OCA bonding and air bonding. Air bonding is to attach the double-sided tape around the iron frame, and then fix the touch panel on top of it. The advantage is that the operation is easy, the cost is low, and the technical threshold is low. The disadvantage is that it is only pasted on four sides, and there will be an air layer in the middle, after refraction, a double image will be produced, and the picture effect is slightly worse, and it is difficult to attract the interest of high-tech product manufacturers.

OCA bonding is to use solid transparent optical glue or liquid transparent optical glue to fully bond the touch panel and the glass layer. Since the two-layer boards are completely tight, there are no gaps and air layers, so the backlight of the display panel can penetrate the glass surface more smoothly, and there will be no overlap caused by photorefraction, showing high brightness and high brightness. Quality, while reducing the overall thickness.

Business elites also use physical objects to understand which products are suitable for the corresponding bonding process, While everyone understands the product through physical objects, they also asked some questions, and engineer gave answers one by one.

Through this product knowledge training, our business product knowledge and skills have improved to a new level. Meanwhile, We will also organize training from time to time about frequently asked questions by customers and our R&D products. With our professional product knowledge and excellent sales department group, we will definitely provide all customers with unique services . Let us look forward to the next sharing together !

Skype

Skype WhatsApp

WhatsApp Email

Email Inquiry

Inquiry WeChat

WeChat

TOP

TOP