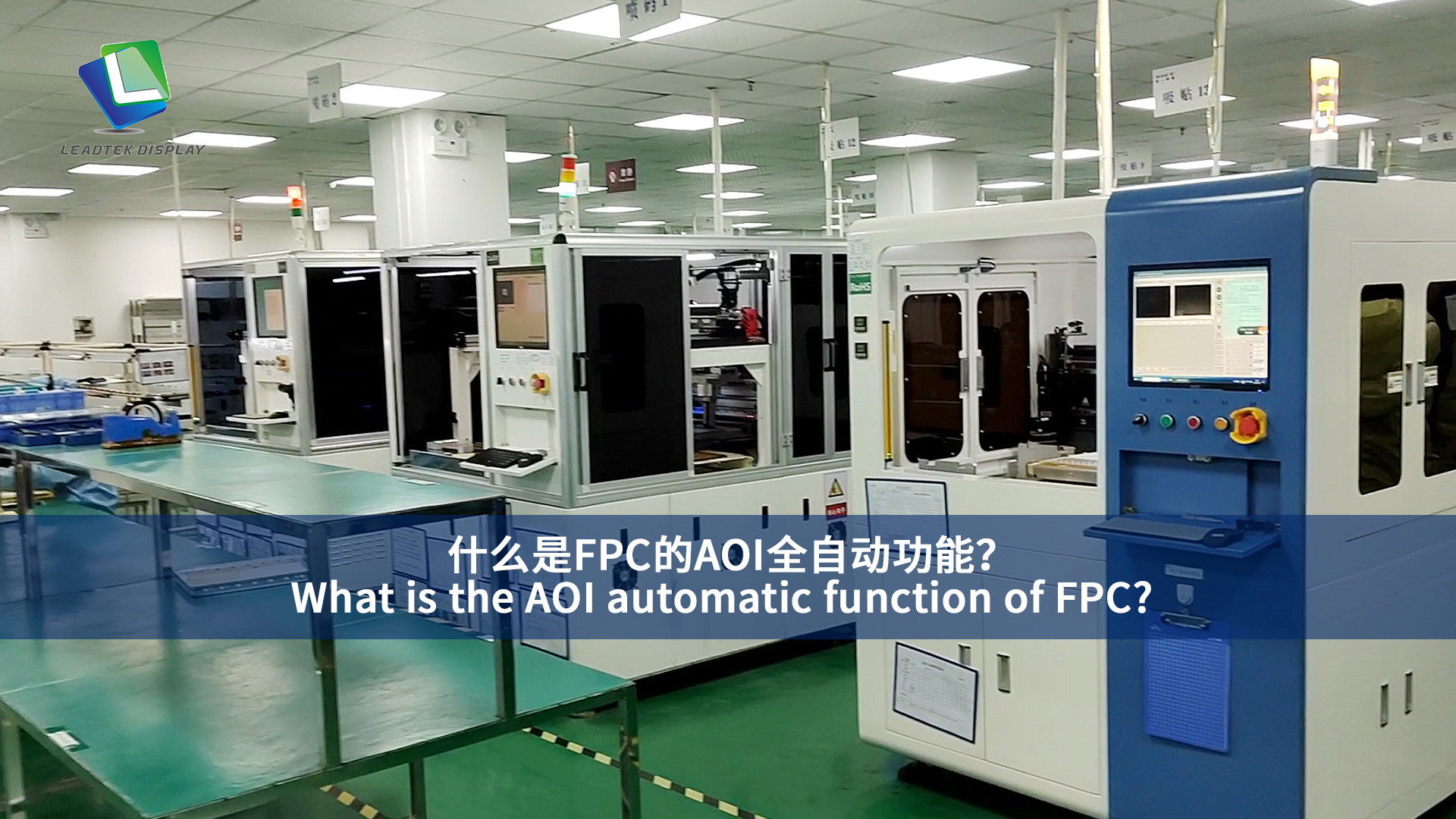

What is the AOI automatic function of FPC?

The electronics industry is developing faster and faster, and the demand for flexible circuit boards (hereinafter referred to as FPCs), which are widely used in electronic equipment, is also increasing.

There is a process in the processing of FPC, which needs to paste auxiliary materials on the FPC. The traditional method of mounting by workers is slow and inefficient, which can no longer meet the production requirements.

Intelligent position recognition, positioning and correction of materials and FPC are carried out through three CCD cameras. The placement heads on both sides of the machine work at the same time, and the whole process is automated.

Its working principle is:

1.A CCD camera locates the FPC, and analyzes all the positions that need to be pasted with accessories.

2.The placement head obtains the mounting material from the feeding platform, and then moves to the CCD cameras on both sides to take pictures, and analyzes the pictures to obtain the material's X, Y and rotation direction offset.

3.Convert the corrected material coordinates to the coordinates on the FPC, and the mounting head moves to the corresponding position to paste the material.

Leadtek supports custom FPC shape, PIN definition and multiple interfaces, committed to research and development, manufacturing and sales of LCD screens, touch screens and comprehensive display solutions

If you have any inquiries about the display screen, please do not hesitate to contact us, our team will provide you with a professional comprehensive display screen solution as soon as possible

Skype

Skype WhatsApp

WhatsApp Email

Email Inquiry

Inquiry WeChat

WeChat

TOP

TOP